Essential questions that are very conspicuous for piping job interviews and may ask by interviewers. These essential facts of the piping field must know if you are working in the piping field.

Codes and Standards

What is the ASTM Codes for various types of pipes?

ASTM Code for pipes are:

ASME Sec-IX-Welding and Brazing Qualifications.

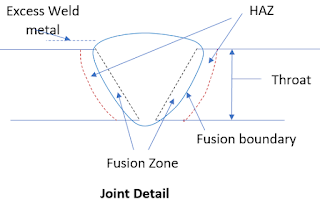

Explain the joint detail drawing?

ASTM Code for pipes are:

- ASTM A 106-Standard Specification for Seamless C.S Pipe for High-Temperature Service

- "ASTM A 312-Standard Specification for Seamless and Welded Austenitic

- Stainless Steel Pipes"

- "ASTM A 333-Standard Specification for Seamless and Welded Steel Pipe for Low-Temperature

- Service"

- ASTM A 105-Standard Specification for C.S Forgings for Piping Applications

- "ASTM A 234-Standard Specification for Piping Fittings of Wrought Carbon Steel and

- Alloy Steel for Moderate and High-Temperature Service"

- ASTM A 193-Standard Specification for Alloy-Steel and Stainless Steel Bolting Materials for High-Temperature Service

- ASTM A 216-Standard Specification for Steel Castings, Carbon, Suitable for Fusion Welding, for High-Temperature Service

- ASTM A 672-Standard Specification for Electric-Fusion-Welded Steel Pipe for High-Pressure Service at Moderate Temperatures

- "ASTM A 182-Standard Specification for Forged or Rolled Alloy-Steel Pipe Flanges,

- Forged Fittings, and Valves and Parts for High-Temperature Service"

- ASTM A 403-Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings

- ASTM A 351-Standard Specification for Castings, Austenitic, Austenitic-Ferritic (Duplex), for Pressure-Containing Parts

- ASTM A 358-Standard Specification for Electric-Fusion-Welded Austenitic Chromium-Nickel Alloy Steel Pipe for High-Temperature Service

- ASTM A 350-Standard Specification for Carbon and Low-Alloy Steel Forgings, Requiring Notch Toughness Testing for Piping Components

- ASTM A 420-Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Low-Temperature Service

- ASTM A 320-Standard Specification for Alloy/Steel Bolting Materials for Low-Temperature Service

- "ASTM A 352-Standard Specification for Steel Castings, Ferritic and Martensitic, for pressure-containing Parts, Suitable for Low-Temperature Service.

What is the formula to calculate Pipe bevel for 37.5 degrees?

tan*degree=answer*thickness

What degree should the pipe bevel be for pipe fittings?

37.5°,

Explain the Unequal pipe tee branch

formula?

Branch pipe OD*Branch pipeOD=A, HEADER OD*4=B

A/B=CUT BACK.

How many types of joints are there between pipe and valve?

But joint

Socket joint

Flanged joint

Screwed joint

What is the purpose of jacket piping?

To heat or maintain the temperature in a line to prevent fluid

congealing, solidification, hydrate formation 'in gas lines, or damage to piping, instrument or equipment.

What is the formula for extracting the degree of rolling pipe in an isometric pipe drawing?

To heat or maintain the temperature in a line to prevent fluid

congealing, solidification, hydrate formation 'in gas lines, or damage to piping, instrument or equipment.

Directions/DirectionA=Answer than Inverse tan*Answer=Degree.

What is a method statement for piping and what is its purpose?

A method statement is a procedure to covers material control (storage and handling). The purpose of MS(method statement) is to define the methods and processes to be adopted in order to ensure that all piping systems are installed in accordance with project specifications.

What is ITP?

A method statement is a procedure to covers material control (storage and handling). The purpose of MS(method statement) is to define the methods and processes to be adopted in order to ensure that all piping systems are installed in accordance with project specifications.

What is ITP?

0 Comments